other Solo pages

Other "green" technology

Links back:

![]()

Design and construction

|

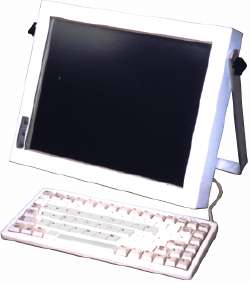

Prototype Mk IIEuropean-style with aluminium composite external casing to comply with regulations on electro-magnetic interference.The brushed aluminium handle folds flat for storage and transportation or can be completely removed. Shown here with an optional notebook-style miniature keyboard. |

The Solo is designed for assembly in Third World countries close to its intended market. The construction is deliberately simple, based on a wooden sub-frame into which slide all the electronic modules and screen.

LCD display options dictate the overall size and include

- 8.4" SVGA (800x600) TFT or STN

- 10.4" SVGA (800x600) TFT

- 12.1" XGA (1024x768) TFT

- 13.3" XGA (1024x768) TFT

- 14.1" XGA (1024x768) TFT

Solo's manufactured for Third World use need not employ the external aluminium cladding, and can be finished with the wooden sub-frame visible, and decorated or carved as required.

|

Solo Mk II prototype with case entirely wooden. The wood is treated with bees-wax to offer a level of protection against dirt and humidty.

Low energy electronics reduces the emissions of electromagnetic radiation, thus enabling Solo units to be used without an external aluminium skin within the 3rd world. Behind the Solo is an amorphous silicon solar panel. |

With the exception of the main computer motherboard and power supply most components are glued in place, obviating the need for specialist fixings. Glues are carefully chosen for their strength, resistance to heat & moisture, and the cleaning agents required. Prototypes are trialing a semi-flexible glue which uses citrus-juice as the cleaner/activator.

If required, Solo's can be assembled, configured and repaired using only hand-tools and another Solo to transfer the software across. This enables manufacture to continue in areas where mains electricity supplies are erratic.

| Solo components showing the wooden rails and parts of the DiBond aluminium composite material in its flat form prior to being folded into the European-style outer case. The DiBond is light to transport and is cut on a flat-bed CNC router before being flown to a manufacturing site. |

|